Spirits Maturation Accelerator

Distilling involves a complex biochemical transformation of grains into spirits like liquor or whiskey. The conventional method for producing spirits mandates extended aging periods—Whisky, for instance, requires around 3 years in oak barrels before bottling. However, prolonged maturation cycles often result in significant time and financial investments.

To address this challenge, distillers increasingly explore advanced technologies aimed at accelerating the aging process of spirits, allowing quicker market placement. Modern techniques such as gamma irradiation, ultrasonic waves, AC electric fields, and micro-oxygenation have emerged for this purpose. However, these methods necessitate specialized expertise and additional power usage.

In contrast, HKE resonance technology offers an accelerated physical maturation approach that doesn’t rely on external power, heat, condensation, or additives during the aging process. This innovative approach doesn't replace traditional aging but complements it, allowing for quicker chemical reactions post-HKE physical resonance. For example, isopropanol reacting with fatty acids forms ester molecules, imparting classic whisky flavors due to HKE's exceptional penetration and potent kinetic energy.

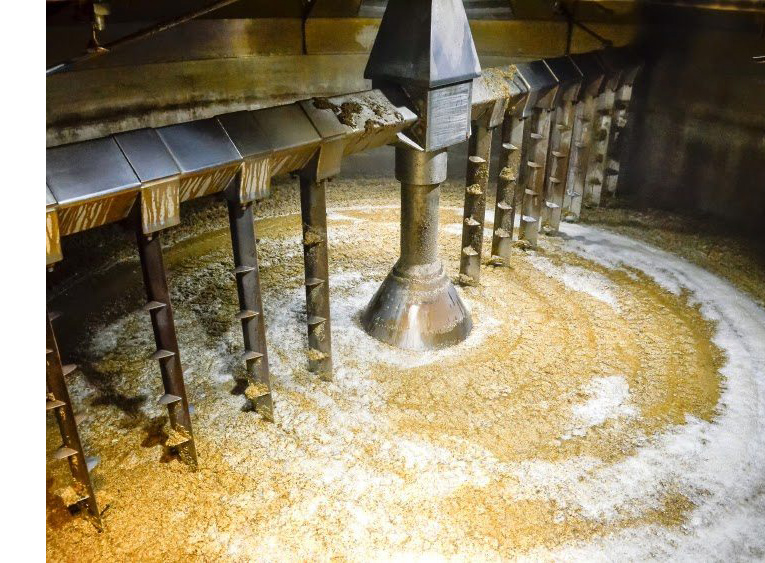

Malting & Mashing

Our maturation acceleration technology extends beyond distillation and encompasses water usage during the malting and mashing stages

as well. By utilizing the HKE hexagonal water generator, we can introduce hot water at approximately 63.5°C into the mash tank, enhancing the process. This hexagonal water, characterized by micro-molecular clusters, offers remarkable water activation, rapid movement speed, high oxygen content, excellent penetration, and strong solubility. These properties effectively stimulate malt enzymes, facilitating the conversion of grain starches into fermentable sugars.

as well. By utilizing the HKE hexagonal water generator, we can introduce hot water at approximately 63.5°C into the mash tank, enhancing the process. This hexagonal water, characterized by micro-molecular clusters, offers remarkable water activation, rapid movement speed, high oxygen content, excellent penetration, and strong solubility. These properties effectively stimulate malt enzymes, facilitating the conversion of grain starches into fermentable sugars.Distillation

In addition to its benefits in the malting and mashing stages, the physical resonance core, placed at

the bottom of the distiller chamber, also proves to be highly advantageous in the distillation process. By incorporating this innovative technology, we can achieve exceptional results in terms of flavor enhancement, purity, and efficiency. The physical resonance core operates by harnessing the principles of molecular resonance, allowing for precise control over the separation and purification of alcohol. This results in a more refined and smoother end product, with minimized impurities and undesirable flavors. Furthermore, the physical resonance core optimizes energy utilization, reducing operating costs and environmental impact. Its advanced design and functionality make it an indispensable tool for distilleries aiming to produce high-quality spirits consistently.

the bottom of the distiller chamber, also proves to be highly advantageous in the distillation process. By incorporating this innovative technology, we can achieve exceptional results in terms of flavor enhancement, purity, and efficiency. The physical resonance core operates by harnessing the principles of molecular resonance, allowing for precise control over the separation and purification of alcohol. This results in a more refined and smoother end product, with minimized impurities and undesirable flavors. Furthermore, the physical resonance core optimizes energy utilization, reducing operating costs and environmental impact. Its advanced design and functionality make it an indispensable tool for distilleries aiming to produce high-quality spirits consistently.

Traditional and Nontraditional Maturation Techniques Can Mutually Works

Traditional and Nontraditional Maturation Techniques Can Mutually WorksTraditional and nontraditional maturation techniques needn’t be mutually exclusive. More and more distillers combine traditional barrel aging with a variety of new techniques designed to accelerate maturation of the finished spirits. The newly made spirits after HKE physical resonance can quickly have chemical reaction such as isopropanol react with fatty acids to form ester molecules, which impart many of the classic whisky flavours, thanks to its high penetration and strong kinetic energy.

Benefits of Using This Technology

Benefits of Using This TechnologyHKE technology is an accelerated physical maturation method. During the accelerated aging process, there is no need for power, heating, condensation, gasification, or any additives.

Accelerates aging time, increasing revenue. Traditional aging can take years, while HKE technology significantly shortens this process.

Low isobaric and strong penetration. Spirits treated with HKE accelerated maturation technology will have a faster metabolism and reduced hangover effects.

Preserves natural flavors. Since no chemical additives or artificial flavorings are used, this technology preserves the natural flavors of the liquid.

Environmentally friendly and energy-efficient. Without the need for heating and condensation, HKE technology is more eco-friendly and energy-efficient.

Enhances flavor complexity. Spirits processed with HKE technology have more complex and layered flavors and aromas.

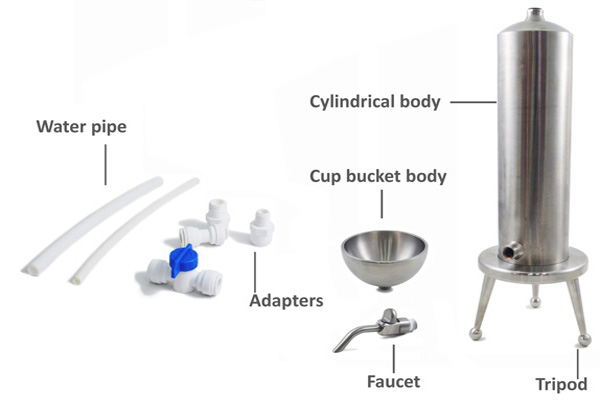

Equipment Indication

Equipment Indication

| Material | 316L Stainless steel, Medical grade |

| Coiled Pipe | 6M seamless coiled pipe, 0.5" |

| Maximum Flow Rate | 1800ml/ minute |

| Inner Pipe Capacity | 4000ml |

| Initial Flow Rate | 3 seconds |

| Height (feet included) | 530mm |

| Diameter (Outer) | 102mm |

| Weight | 13.6Kg (N. W.); 14.5Kg (G.W.) |

| Half-life Period | 10 years |

| ODM Service | Yes, customize design support |

| Package (Box) | 520 (L) x 210 (D) x 340 (H) mm |